The temperature rise test is a fundamental procedure in evaluating the performance and safety of dry-type transformers. This test ensures that the transformer operates efficiently and within safe temperature limits, preventing potential failures and prolonging its lifespan. In this article, we delve into the importance, methodology, and standards associated with the temperature rise test for dry-type transformers.

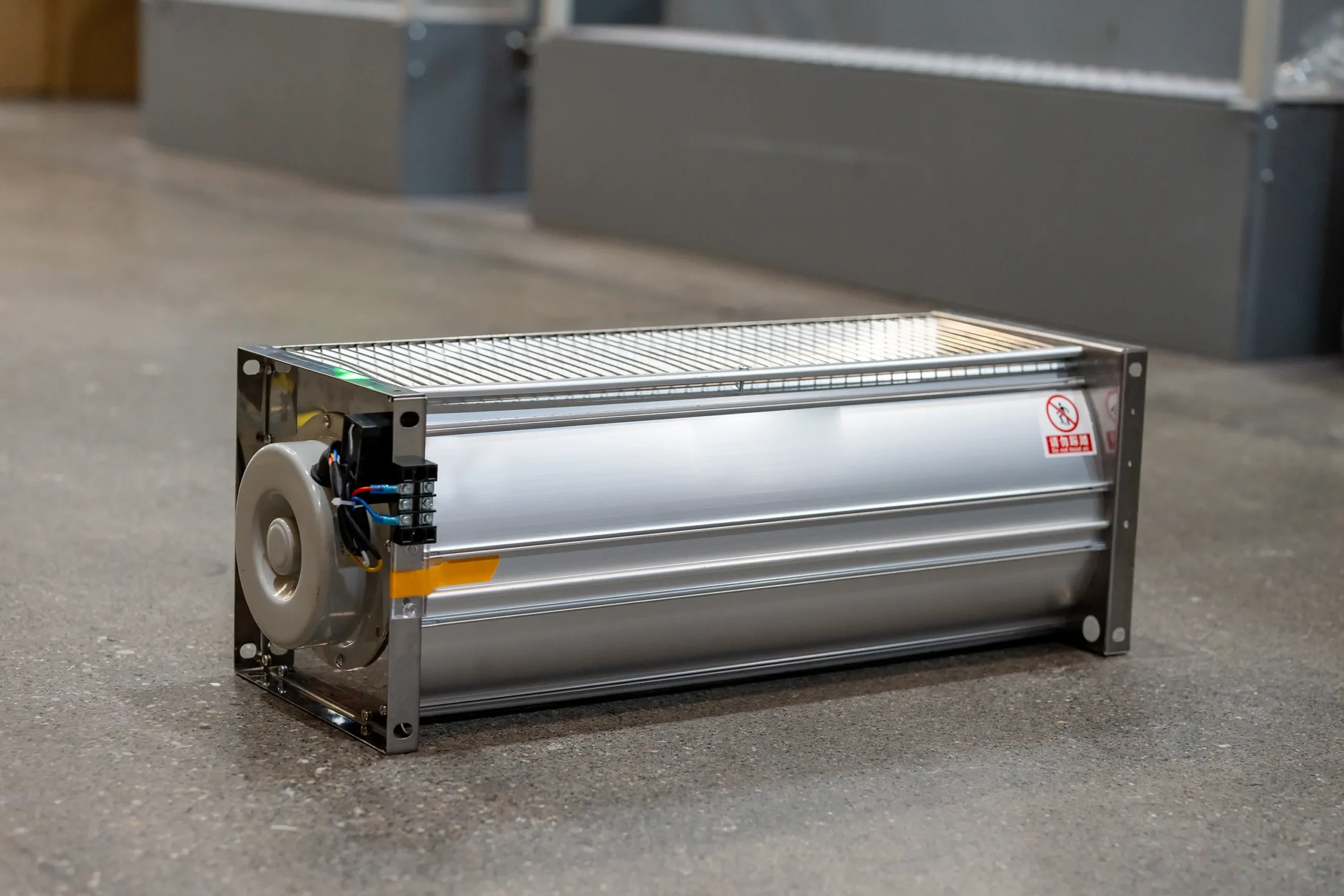

Dry-type transformers are electrical devices that use air as a cooling medium instead of liquid. They are typically used in environments where fire safety is a priority, such as in buildings, factories, and commercial areas. Because they do not contain flammable liquids, they offer an added layer of safety against fires.

Importance of Temperature Rise Testing

Temperature rise testing is crucial for several reasons:

- Electrical Safety: Ensures the transformer operates within safe temperature limits, reducing the risk of overheating and potential fire hazards.

- Transformer Performance: Evaluates the efficiency of the transformer under load conditions and its ability to dissipate heat.

- Insulation Testing: Checks the integrity of the insulation system, which is critical for preventing electrical failures.

Conducting a Temperature Rise Test

Temperature rise testing involves measuring the temperature increase of the transformer’s windings and core under specific load conditions. Here’s a step-by-step guide to the process:

1. Preparing the Transformer

Before beginning the test, ensure that the transformer is properly installed and all connections are secure. The transformer should be at ambient temperature before testing begins.

2. Applying the Load

The transformer is subjected to its rated load, and sometimes to an overload condition, to simulate real-world operating conditions. The test is typically conducted over a period sufficient to achieve thermal stability, which can take several hours.

3. Measuring Temperature

Temperature sensors are placed at strategic points on the transformer to monitor the temperature rise. The most critical measurements are taken at the winding and core, as these areas are most susceptible to overheating.

4. Calculating Temperature Rise

The temperature rise is calculated as the difference between the measured temperature under load and the ambient temperature. This value is then compared to the allowable temperature limits specified by transformer standards.

Transformer Standards and Temperature Limits

Adhering to transformer standards is essential for ensuring safety and performance. The IEC (International Electrotechnical Commission) and IEEE (Institute of Electrical and Electronics Engineers) provide guidelines on acceptable temperature rise limits for dry-type transformers.

Key Standards for Temperature Rise

- IEC 60076-11: Specifies the temperature rise limits for dry-type transformers, ensuring they operate safely under various conditions.

- IEEE C57.12.01: Provides guidelines for the design and testing of dry-type transformers, including temperature rise testing.

These standards help manufacturers and operators ensure that their transformers meet safety and performance requirements.

Thermal Testing and Heat Dissipation

An effective temperature rise test not only evaluates the transformer’s ability to operate safely under load but also its capability to dissipate heat. Proper heat dissipation is crucial to avoid overheating and extend the transformer’s lifespan.

Factors Influencing Heat Dissipation

- Design of the Transformer: A well-designed transformer will efficiently dissipate heat through its core and windings.

- Ambient Conditions: Higher ambient temperatures can impact the transformer’s ability to dissipate heat, making accurate testing conditions critical.

- Ventilation: Adequate ventilation around the transformer helps in effective heat dissipation, preventing excessive temperature rise.

Importance of Regular Testing

Regular temperature rise testing is essential for maintaining the health and performance of dry type transformers. Scheduled testing helps identify potential issues early, reducing the risk of unexpected failures and extending the transformer’s operational life.

Benefits of Regular Testing

- Increased Reliability: Regular testing ensures that transformers remain reliable and efficient in their operations.

- Cost Savings: Early detection of issues can prevent costly repairs and downtime.

- Safety Assurance: Ongoing testing guarantees that transformers operate within safe temperature limits, minimizing risks to personnel and property.

Conclusion

Temperature rise testing is a critical component in the maintenance and operation of dry type transformers. By understanding and implementing the appropriate testing procedures and adhering to industry standards, businesses can ensure the safety, performance, and longevity of their transformers. Regular testing not only safeguards against potential failures but also optimizes transformer efficiency, providing peace of mind and operational assurance.

In conclusion, prioritizing temperature rise testing and adhering to transformer standards are essential for achieving optimal transformer performance. Whether you’re a facility manager, engineer, or technician, understanding the importance of these tests can help you maintain a safe and efficient electrical system.

By keeping transformers within their operational temperature limits, you not only ensure their longevity but also enhance the overall safety and reliability of your electrical infrastructure.