Understanding the heat loss in a dry-type transformer is crucial for ensuring its efficiency and longevity. Transformers play a vital role in electrical systems by stepping up or stepping down voltage levels to meet specific requirements. However, during this process, transformers naturally generate heat due to various losses. This heat generation can impact the performance and lifespan of the transformer if not properly managed. In this article, we will explore the concepts of heat loss in dry-type transformers, the factors contributing to these losses, and how to calculate them effectively.

Efficient management of heat loss is not just about maintaining performance but also about reducing operational costs. Heat losses represent wasted energy, and minimizing them can lead to significant savings. Furthermore, understanding these losses enables better design and operational decisions, contributing to more sustainable energy use. We’ll delve into the types of losses, methods for calculating them, and strategies for enhancing transformer efficiency.

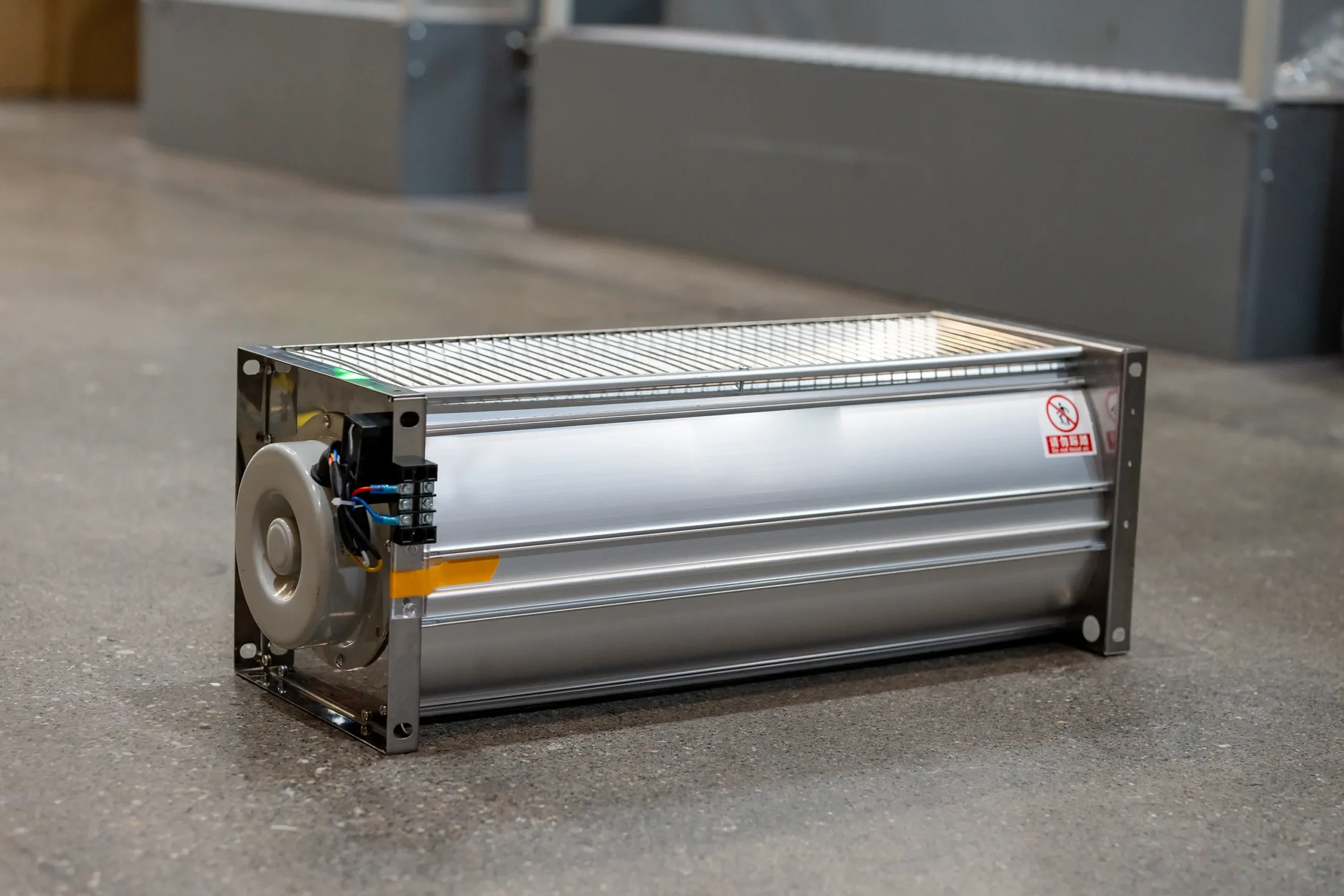

A dry-type transformer, unlike oil-filled transformers, uses air as the cooling medium. It is designed with solid insulation and doesn’t require any liquid to cool its system, making it a safer and more environmentally friendly option. This makes it an ideal choice for indoor applications where environmental and safety concerns are paramount. They are commonly used in hospitals, high-rise buildings, and other spaces where oil leakage could pose a significant risk.

Despite being safer and more environmentally friendly, dry-type transformers are not immune to losses that result in heat generation. These losses, if not managed, can lead to overheating, reducing the transformer’s efficiency, and potentially causing damage. Understanding these losses is essential for optimizing the transformer’s performance and extending its operational life. Let’s explore the types of losses that occur in these transformers.

Types of Losses in Transformers

To understand heat loss in dry-type transformers, it’s essential to break down the types of losses that occur. These losses can be broadly categorized into two main types: core losses and copper losses. Each type of loss has unique characteristics and contributes differently to the overall heat generation.

Core Losses

Core losses, also known as iron losses, occur in the transformer’s core. They are mainly due to the alternating magnetic field, which causes hysteresis and eddy current losses in the core material. Hysteresis loss is related to the lag between the magnetic field and the magnetization of the core, while eddy current loss is due to the induced currents in the core. Core losses are constant and occur whenever the transformer is energized, regardless of the load.

Core losses are influenced by the quality of the core material and its design. High-quality core materials with low hysteresis and eddy current losses can significantly reduce these losses. Manufacturers often provide data on core losses, allowing for accurate calculations and better design choices. Understanding core losses is crucial for ensuring that the transformer operates efficiently, especially when it is lightly loaded.

Copper Losses

Copper losses, also known as load losses, occur in the transformer’s windings. They are caused by the resistance in the winding wires and vary with the load. Copper losses increase as the load increases, following the formula P = I²R, where ‘P’ is the power loss, ‘I’ is the current, and ‘R’ is the resistance of the winding. These losses are more prominent under heavy load conditions and can significantly impact transformer performance.

Minimizing copper losses involves optimizing the winding design to reduce resistance and improve current distribution. High-quality conductors and precise manufacturing processes are essential for achieving low resistance. By carefully managing copper losses, transformers can operate more efficiently, especially during peak load times, resulting in energy savings and extended equipment life.

Stray Losses

Stray losses arise from leakage flux that doesn’t follow the intended magnetic circuit path. These losses are generally small but can contribute to the overall heat generated in the transformer. Stray losses occur due to imperfections in the magnetic circuit and variations in load conditions.

While stray losses are often considered negligible, they can become significant in certain applications, especially in high-power transformers. Designers must account for these losses during the design and testing phases to ensure accurate performance predictions. By understanding and minimizing stray losses, transformers can be designed to operate more reliably and efficiently.

Understanding Transformer Efficiency

Transformer efficiency is a measure of how well a transformer converts the input power to output power. It is determined by the formula:

Efficiency(%)=(Output Power/Input Power)×100

The efficiency of a transformer is affected by the sum of core and copper losses. Reducing these losses is key to improving the transformer’s efficiency and ensuring it operates within safe temperature limits. A highly efficient transformer not only saves energy but also reduces the operational costs associated with energy losses.

In addition to energy savings, efficient transformers contribute to a more stable and reliable electrical grid. By minimizing losses, transformers generate less heat, reducing the cooling requirements and extending the life of the equipment. Understanding the efficiency of a transformer and the factors that influence it is crucial for selecting the right transformer for specific applications and ensuring optimal performance.

Calculating Heat Loss

Calculating the heat loss in a dry-type transformer involves determining the total power loss, which is the sum of core losses, copper losses, and stray losses. Here’s a step-by-step guide to performing this calculation:

Step 1: Calculate Core Losses

Core losses are determined by the material and design of the transformer core and are typically provided by the manufacturer. These losses can be estimated using the formula:

Core Loss=Hysteresis Loss+Eddy Current Loss

Manufacturers often provide detailed data on core losses, allowing for precise calculations. By understanding these losses, engineers can make informed decisions about material selection and core design to minimize energy waste. Accurate core loss calculations are essential for predicting transformer performance and ensuring efficient operation.

Step 2: Calculate Copper Losses

Copper losses depend on the load current and can be calculated using the formula:

Copper Loss=I2×R

Where ‘I’ is the load current and ‘R’ is the resistance of the winding. It’s important to note that copper losses increase with the square of the load current. As the load increases, copper losses become a more significant factor in the overall heat loss.

Calculating copper losses accurately requires precise measurements of winding resistance and load conditions. By optimizing the winding design and using high-quality materials, these losses can be minimized, resulting in better transformer performance and energy efficiency. Understanding copper losses is crucial for managing transformer loads and ensuring reliable operation.

Step 3: Calculate Stray Losses

Stray losses are usually a small percentage of the total losses and can be estimated based on the transformer’s design and operational data. Manufacturers often provide this information, allowing for accurate calculations. Stray losses are typically considered during the design phase to ensure that they do not exceed acceptable limits.

While stray losses are generally small, they can become significant in certain applications, especially in high-power transformers. By understanding and minimizing stray losses, designers can ensure that transformers operate reliably and efficiently. Accurate stray loss calculations are essential for predicting transformer performance and ensuring optimal operation.

Step 4: Total Heat Loss

The total heat loss is the sum of core, copper, and stray losses:

Total Heat Loss=Core Loss+Copper Loss+Stray Loss

Calculating the total heat loss provides a comprehensive understanding of the transformer’s efficiency and performance. By accurately estimating each type of loss, engineers can design transformers that operate within safe temperature limits and achieve optimal performance. Understanding total heat loss is crucial for managing transformer operation and ensuring reliable performance.

Temperature Rise and Thermal Balance

The temperature rise in a transformer is directly related to heat loss. A higher temperature rise indicates higher losses and can potentially shorten the transformer’s lifespan. Ensuring thermal balance is key to maintaining optimal performance. Proper thermal management involves selecting the right cooling methods and materials to dissipate heat effectively.

Cooling Methods for Dry Type Transformers

To manage the temperature rise and maintain thermal balance, dry-type transformers use various cooling methods:

- Natural Air Cooling: Uses ambient air to cool the transformer, suitable for lower power ratings. This method is simple and cost-effective, but may not be sufficient for high-power applications.

- Forced Air Cooling: Involves fans to increase air circulation, used for higher power ratings. This method enhances cooling efficiency and is suitable for transformers with higher heat generation.

- Air-to-Water Cooling: Utilizes water-cooled heat exchangers for more efficient cooling in high-power applications. This method provides superior cooling performance and is ideal for applications where space and thermal constraints are critical.

Selecting the appropriate cooling method is essential for maintaining thermal balance and ensuring reliable transformer operation. By effectively managing temperature rise, transformers can operate efficiently, reducing energy waste and extending equipment life.

Conclusion

Understanding and calculating heat loss in dry-type transformers is crucial for optimizing their efficiency and longevity. By identifying the sources of losses and implementing effective cooling methods, you can ensure your transformer operates effectively and within safe temperature limits. Efficient transformers not only save energy but also contribute to a more sustainable and reliable electrical infrastructure.

Incorporating these insights into your transformer management practices will help you achieve better performance and reduce operational costs in the long run. By focusing on heat loss reduction and efficiency improvement, you can enhance the reliability and sustainability of your electrical systems, ensuring they meet the demands of modern applications.