Dry-type transformers have become increasingly popular due to their safety, environmental benefits, and reliability. As businesses and industries aim to become more sustainable, the demand for efficient and eco-friendly solutions has risen sharply. However, like any electrical equipment, maximizing their efficiency is crucial for reducing energy costs and minimizing environmental impact. In this article, we will explore how to optimize the performance of dry-type transformers, focusing on key aspects like energy efficiency, minimizing energy loss, and understanding the differences between dry-type and oil-type transformers.

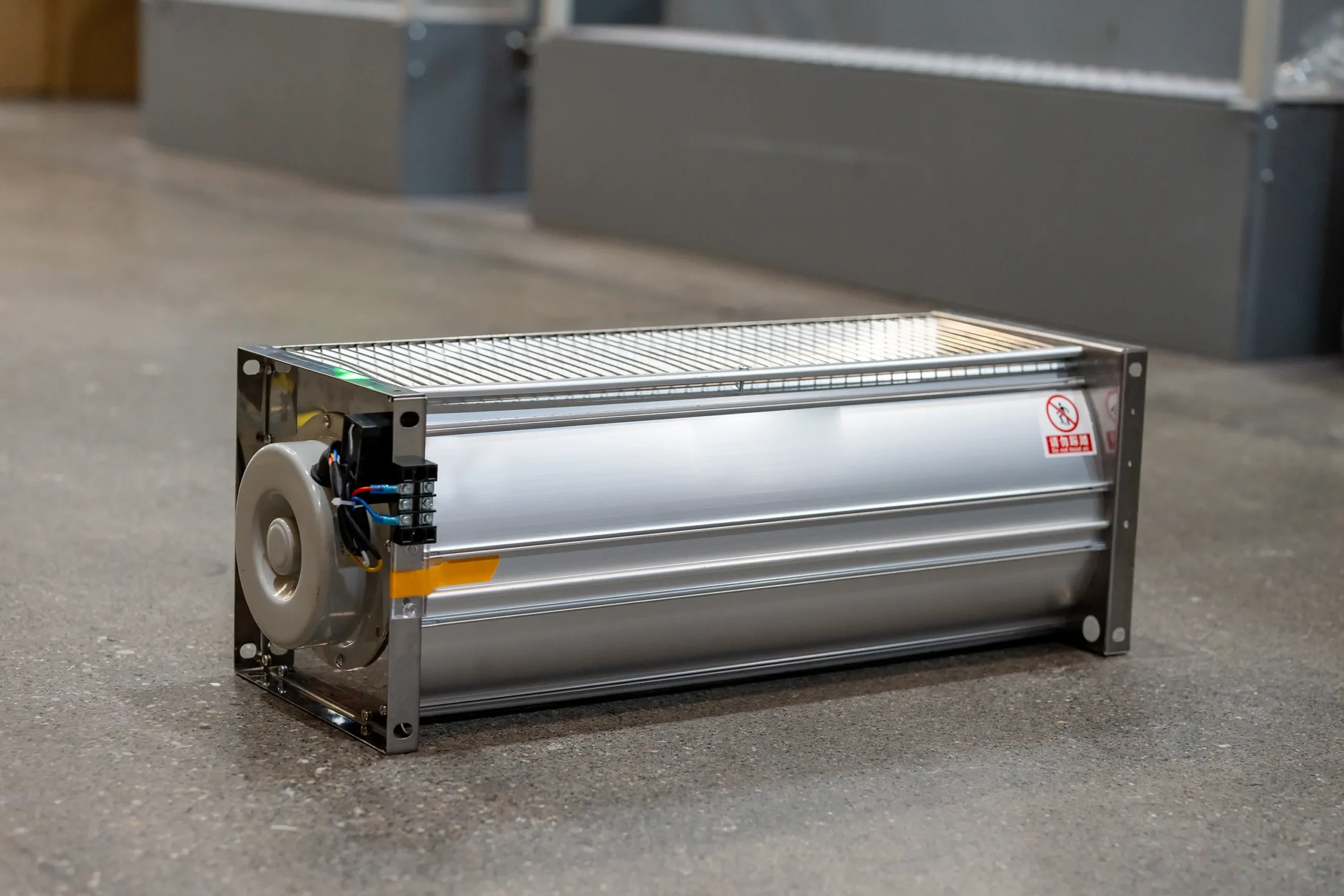

Dry-type transformers are designed to operate without liquid insulation or cooling, using air as the primary cooling medium. This design makes them safer and more environmentally friendly compared to oil-filled transformers. The absence of oil reduces the risk of fire and leakage, making them suitable for indoor applications. However, their efficiency can vary based on several factors, such as the materials used and the conditions in which they operate.

The Importance of Energy Efficiency

Energy efficiency in transformers is critical because it directly affects operational costs and environmental impact. An energy-efficient transformer can significantly reduce electricity consumption, leading to lower utility bills and a reduced carbon footprint. As energy costs continue to rise and environmental regulations become stricter, investing in energy-efficient transformers is not just beneficial but necessary for long-term sustainability. Additionally, efficient transformers contribute to the stability of power systems by reducing the overall demand on power grids.

Factors Affecting Transformer Efficiency

- Core Material: The type of core material used in a transformer impacts its efficiency. High-quality silicon steel cores, for example, can reduce energy loss and improve performance. Grain-oriented steel and amorphous steel are other materials that can enhance efficiency by minimizing hysteresis and eddy current losses.

- Winding Material: The choice between copper and aluminum windings can affect efficiency. Copper is generally more efficient due to its lower resistance. While aluminum is lighter and cheaper, copper’s superior conductivity often leads to better performance, especially in high-load conditions.

- Design and Construction: A well-designed transformer with proper ventilation and cooling mechanisms will operate more efficiently. Advanced design techniques, such as optimizing the winding layout and using precision manufacturing processes, can further enhance performance and reduce energy losses.

Reducing Transformer Energy Loss

Energy loss in transformers occurs primarily through heat generation. Minimizing these losses is essential for improving overall efficiency. By understanding the sources of these losses and implementing targeted strategies, operators can achieve significant energy savings.

Types of Energy Losses

- Core Losses: These occur due to the magnetizing and demagnetizing of the transformer core. They can be minimized by using high-quality core materials. Core losses are largely constant and not dependent on the load, so selecting the right materials at the design stage is crucial for long-term efficiency.

- Copper Losses: Resulting from the resistance of the winding material, these can be reduced by using conductors with lower resistance. Unlike core losses, copper losses increase with load, making it important to manage the transformer load to avoid unnecessary energy waste.

Techniques to Minimize Losses

- Regular Maintenance: Routine inspections and maintenance can help identify issues that lead to energy losses. This includes checking for loose connections, inspecting insulation, and ensuring the cooling system is functioning properly.

- Optimized Load Management: Operating transformers at optimal loads can reduce unnecessary energy losses. Ensuring that transformers are neither underloaded nor overloaded can enhance efficiency and prolong the equipment’s lifespan.

- Advanced Monitoring Systems: Implementing monitoring systems can help track performance and identify inefficiencies. Real-time data analytics can provide insights into energy usage patterns and help in the early detection of potential problems.

Comparing Dry Type and Oil Type Transformers

When considering transformer efficiency, it’s essential to understand the differences between dry-type and oil-type transformers. Both have distinct characteristics that make them suitable for different applications.

Efficiency Comparison

- Dry Type Transformers: Typically have lower efficiency due to air cooling but offer significant safety and environmental advantages. They are ideal for environments where fire risk must be minimized and where environmental regulations are stringent.

- Oil Type Transformers: Generally more efficient due to the better cooling properties of oil, but they pose environmental and safety risks. These transformers are often used in outdoor settings where their higher efficiency can be leveraged without compromising safety.

Application Suitability

- Safety: Dry-type transformers are ideal for indoor applications where fire safety is a concern. Their design reduces the risk of fire and eliminates the potential for oil leakage, making them suitable for schools, hospitals, and commercial buildings.

- Environment: Oil-type transformers are better suited for outdoor applications where efficiency is prioritized over safety. Their ability to handle larger loads and dissipate heat more effectively makes them ideal for industrial and power distribution applications.

Enhancing Cast Resin Transformer Efficiency

Cast resin transformers are a subtype of dry-type transformers, known for their robustness and reliability. They are often used in environments that require high reliability and low maintenance. Improving their efficiency involves specific strategies tailored to their unique design.

Design Improvements

- Use of High-Quality Resins: High-grade resins reduce energy loss and improve the thermal performance of the transformer. These resins encapsulate the windings, providing excellent insulation and protecting against environmental factors.

- Ventilation and Cooling: Ensuring adequate cooling and ventilation enhances efficiency by preventing overheating. Incorporating innovative cooling designs, such as natural air convection or forced air systems, can further improve performance.

Operational Strategies

- Load Management: Efficient load management ensures transformers operate within optimal parameters, reducing stress and energy loss. By analyzing load patterns, operators can adjust usage to align with peak efficiency times.

- Regular Testing: Periodic testing and analysis help maintain optimal performance levels. Diagnostic tools can identify performance issues before they lead to significant energy losses or equipment failure.

Implementing Energy-Efficient Transformers

Adopting energy-efficient transformers can have significant long-term benefits for businesses and the environment. By investing in these technologies, companies can not only reduce costs but also demonstrate their commitment to sustainability.

Benefits of Energy-Efficient Transformers

- Cost Savings: Lower energy consumption translates to reduced electricity bills. The initial investment in energy-efficient transformers can be offset by significant long-term savings on operational costs.

- Environmental Impact: Reduced carbon emissions and environmental footprint. By using transformers that consume less energy, companies contribute to reducing greenhouse gas emissions and conserving natural resources.

- Reliability and Longevity: Energy-efficient transformers tend to have a longer lifespan and require less maintenance. This reliability translates to fewer interruptions and lower repair costs over the equipment’s lifetime.

Selecting the Right Transformer

When choosing a transformer, consider factors such as:

- Load Requirements: Ensure the transformer matches your specific load requirements for optimal performance. Proper sizing prevents inefficiencies and ensures the transformer can handle peak loads without excessive energy loss.

- Efficiency Ratings: Look for transformers with high efficiency ratings to maximize energy savings. Certifications and standards, such as those from the DOE or Energy Star, can guide you in selecting the best option.

Conclusion

Maximizing the efficiency of dry-type transformers is essential for reducing operational costs and minimizing environmental impact. By understanding the factors affecting transformer efficiency, implementing strategies to reduce energy losses, and choosing the right type of transformer for your needs, you can achieve significant efficiency gains. Whether you’re considering upgrading existing transformers or investing in new ones, prioritizing energy efficiency will lead to long-term benefits for your business and the planet. As technology advances, staying informed about the latest developments in transformer efficiency can further enhance your ability to make informed decisions that support both economic and environmental goals.