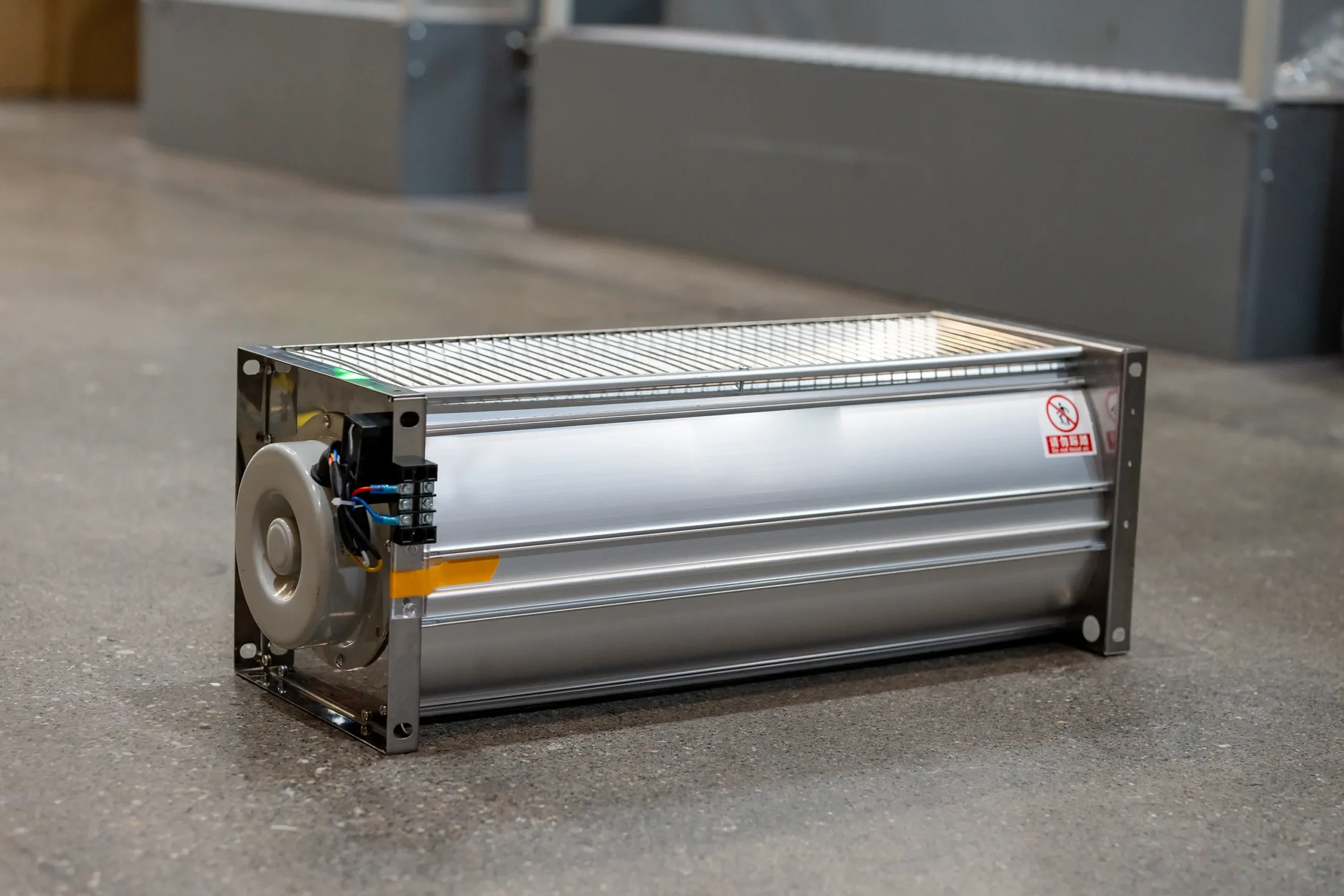

Dry-type transformers are electrical transformers that use air as the cooling medium instead of oil or other liquids. They are typically used in indoor applications where safety and environmental concerns are paramount. These transformers are known for their durability and require less maintenance compared to their oil-filled counterparts. Their design minimizes the risk of spills and leaks, making them a preferred choice in settings where environmental protection is a priority.

Key Features of Dry Type Transformers

- Safety: Since they do not use flammable oil, dry-type transformers pose a lower fire risk. This is particularly advantageous in urban areas or inside buildings where safety is a top concern. The absence of oil also reduces the risk of smoke and toxic fumes in the event of a malfunction.

- Eco-friendly: The absence of oil reduces the risk of soil contamination and environmental hazards. This makes dry-type transformers an attractive option for companies looking to reduce their ecological footprint. Moreover, they eliminate the need for oil disposal procedures, further enhancing their environmental credentials.

- Minimal Maintenance: These transformers require less frequent maintenance, contributing to their longevity. This is due in part to their robust design and fewer moving parts, which reduces the likelihood of mechanical failures. The lower maintenance requirements also translate to reduced operational costs over the transformer’s lifetime.

Factors Influencing Transformer Life Expectancy

The lifespan of a dry-type transformer is influenced by several factors. Understanding these can help in enhancing transformer reliability and efficiency. By identifying and addressing these factors, operators can prevent premature failures and optimize performance.

Insulation Aging

The insulation system is the heart of a transformer. Over time, the insulation materials deteriorate due to thermal, electrical, and mechanical stresses. This process, known as insulation aging, is a primary factor affecting transformer lifespan. Regular monitoring and maintenance can mitigate the effects of insulation aging, thus prolonging the service life of the transformer. Furthermore, choosing high-quality insulation materials can delay the onset of aging, providing an additional layer of protection for the transformer.

Thermal Management

Heat is a significant enemy of transformers. Excessive heat can accelerate insulation aging and reduce the transformer’s efficiency. Effective thermal management, including proper ventilation and temperature monitoring, is crucial in maintaining the transformer’s health and extending its lifespan. Advanced cooling technologies and systems can be implemented to ensure the transformer operates within safe temperature limits. By investing in enhanced cooling solutions, operators can significantly reduce the risk of heat-related damage.

Load Management

Operating a transformer beyond its rated capacity can lead to overheating and increased wear and tear. Proper load management ensures that the transformer operates within its designed limits, thereby enhancing its durability and service life. Regular load assessments can help in determining whether the transformer is being used optimally. By adjusting load distributions and ensuring balanced operations, operators can prevent overloading and extend the lifespan of the transformer.

Maintenance Practices for Extending Transformer Lifespan

Regular maintenance is essential to ensure the longevity and reliability of dry-type transformers. Here are some key maintenance practices to consider. These practices not only help in preventing failures but also enhance overall performance.

Regular Inspections

Conducting regular visual inspections can help identify potential issues before they escalate into major problems. Checking for signs of wear, corrosion, and insulation degradation is vital in preventing unexpected failures. Inspections should also include assessments of the transformer’s structural integrity and connections. By scheduling routine inspections, operators can address small issues before they develop into costly repairs.

Cleaning and Dust Removal

Dust and debris accumulation can impact the cooling efficiency of dry-type transformers. Regular cleaning helps maintain optimal thermal management and prevents overheating. In addition to regular dusting, implementing air filtration systems can minimize airborne particles that settle on the transformer. This proactive approach ensures that the transformer remains clean and efficient, reducing the risk of thermal inefficiency.

Electrical Testing

Periodic electrical testing, including insulation resistance and power factor tests, can provide insights into the transformer’s condition. These tests help in identifying potential faults and planning preventive maintenance. Advanced diagnostic tools can offer more detailed analysis, pinpointing specific areas of concern. Incorporating these tests into routine maintenance schedules enhances the transformer’s reliability and operational safety.

Enhancing Transformer Efficiency

Efficiency is a critical aspect of transformer performance. Implementing strategies to enhance transformer efficiency can lead to significant energy savings and a prolonged service life. By focusing on efficiency, operators can achieve both economic and environmental benefits.

Upgrading Components

Replacing outdated components with modern, energy-efficient ones can improve the transformer’s overall efficiency. For instance, using advanced insulation materials can reduce energy loss and extend the transformer’s lifespan. Additionally, upgrading to components with better thermal properties can enhance heat dissipation. By investing in these upgrades, operators can achieve long-term savings and improved performance.

Implementing Smart Technologies

Integrating smart technologies, such as condition monitoring systems, can provide real-time data on the transformer’s performance. These systems enable proactive maintenance and help in optimizing the transformer’s operation. Smart technologies can also provide predictive analytics, allowing operators to anticipate issues before they arise. By leveraging these tools, transformers can achieve greater efficiency and reliability.

The Impact of Environmental Conditions

Environmental conditions play a significant role in determining the lifespan of dry-type transformers. Factors such as humidity, temperature fluctuations, and pollution levels can influence the transformer’s performance and durability. Understanding and mitigating these environmental impacts is crucial for maintaining optimal transformer function.

Humidity Control

Excessive humidity can lead to moisture ingress, which affects the insulation system’s integrity. Implementing humidity control measures, such as dehumidifiers and sealed enclosures, can protect the transformer from moisture-related issues. Regular monitoring of humidity levels can further ensure that conditions remain within safe limits. By maintaining a dry environment, operators can prevent corrosion and insulation degradation.

Pollution Prevention

Pollution can lead to the accumulation of contaminants on the transformer’s surface, impacting its cooling efficiency and performance. Regular cleaning and the use of protective coatings can mitigate the effects of pollution. Installing barriers or shelters can also reduce exposure to pollutants. By taking these preventive measures, transformers can maintain their efficiency and extend their operational life.

Conclusion

In conclusion, understanding the factors that influence the lifespan of dry-type transformers is crucial for ensuring their reliability and efficiency. By focusing on insulation aging, thermal management, and regular maintenance, you can significantly extend the service life of these vital components. Additionally, integrating smart technologies and addressing environmental challenges can further enhance transformer durability and performance. With proper care and attention, dry-type transformers can continue to provide safe and efficient electricity distribution for many years. By implementing these strategies, operators can ensure that transformers remain a reliable cornerstone of electrical infrastructure.